PANATERM for Safety – Safe Torque Off (STO)

Before you start

Before operating this product, read the safety instructions in the following manuals:

This product is for industrial use only.

Electrical connections must be made by qualified electrical personnel.

Description

Step by step instructions will guide you through configuring and programming the Safe Torque Off function (STO) with the programming software PANATERM for Safety.

Available software

The following software is available free of charge in our Panasonic Download Center.

Functional overview

The Safe Torque Off function (STO) disables the torque on the drive by immediately switching off power supply to the motor. The STO function can be used for emergency stops and to prevent unexpected restarting of the machine.

Use the programming software PANATERM for Safety to set up this function for the MINAS A6 Multi servo drive system.

[t0,t1[ |

Movement with initial speed |

t1 |

The STO function is initiated |

Example

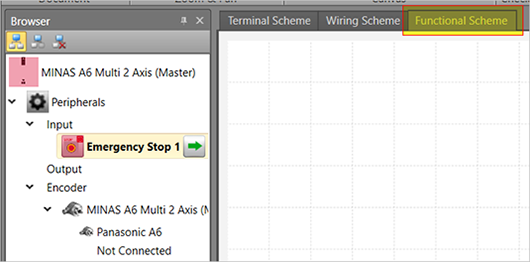

A servo drive system, consisting of a 15kW power supply module, an A-size 1.5kW two-axis driver module, and two servo motors with 1.0kW and 1.5kW, is connected to a PC by a USB cable.

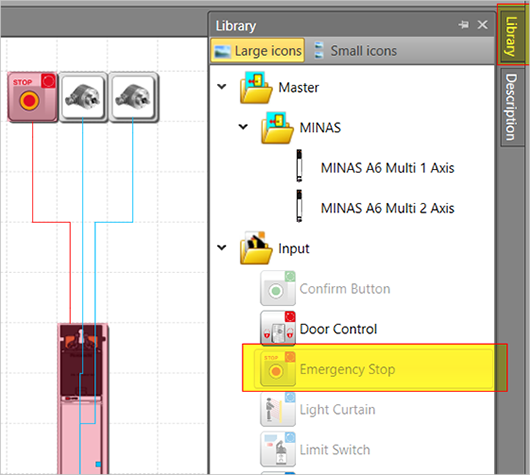

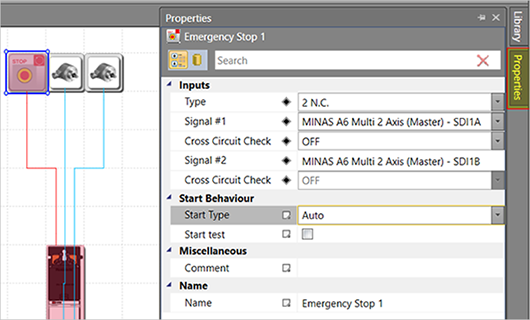

An emergency stop button is connected to the MINAS A6 Multi driver module.

Use the following accessories:

1 x 400V AC power supply cable: Connects the MINAS A6 Multi power supply module to the main power supply (400V AC).

1 x 24V DC power supply cable: Connects the power supply unit (24V DC) and the host controller.

1 x grounding wire (M4 round terminal): Connects the PE terminals of the power supply module and the driver module.

2 x Panasonic motor cable: Connects the motor and the driver module.

2 x Panasonic encoder cable: Connects the encoder and the driver module.

1 x RJ11 communication cable (2 x RJ11 plug): Connects the power supply module and the driver module.

1 x feed bus bar (50mm) with end cap for the DC link bus (535V DC to 675V DC): Connects the power supply module and the driver module.

1 x feed bus bar (50mm) with end cap for the control bus (24V DC): Connects the power supply module and the driver module.

1 x emergency stop button connected to the driver module

1 x USB license dongle

1 x USB cable

- (1) Power supply unit (24V DC)

- (2) MINAS A6 Multi power supply module (400V AC, 15kW)

- (3) Two-axis MINAS A6 Multi driver module (1.5kW)

- (4) USB cable between PC and driver module

- (5) Emergency stop button

- (6) MINAS A6 servo motor B (1.5kW)

- (7) MINAS A6 servo motor A (1kW)

- (8) USB license dongle for PANATERM for Safety

- (9) PC with PANATERM for Safety

Wiring

Recommendations for wiring

It is the customer's responsibility to apply the countermeasures that they consider necessary to comply with current regulations on wiring, safety and reducing EMI.

Do not forget to meet the specifications indicated in the hardware manual for each of the devices being wired. If any specifications in the manual conflict with the information in this document, the manufacturer's manual takes preference.

For detailed information on reducing EMI, please refer to Recommendations for EMC-compliant wiring of servo drivers and motors.

Bottom side connectors of the servo drive system

The image shows the most important connectors of a power supply module (left) and a driver module (right). Please refer to the technical documentation for details about other connectors.

- (1)

X102: Main power supply (400V AC)

Connect the 400V AC main power supply cable to X102. Connect the PE terminals of the power supply module and the driver module by a grounding wire.

- (2)

X11: Control power supply (24V DC)

Connect the 24V DC control power supply to X11.

- (3)

X105A: Motor A, (4) X105B: Motor B

Connect the motor cable for servo motor A to X105A and the motor cable for servo motor B to X105B.

- (4)

X9A: Encoder A, (6) X9B: Encoder B

Connect the cable of encoder A to X9A and the cable of encoder B to X9B.

Top side connectors of the servo drive system

The image shows the most important connectors of a power supply module (left) and a driver module (right). Please refer to the technical documentation for details about other connectors.

- (1)

X1: Internal communication connector on power supply module, (2) X1A: Internal communication connector on driver module

Connect X1 and X1A with the RJ11 communication cable.

- (3)

X6A: EtherCAT communication connector on driver module (not used in this example)

Front side connectors of the servo drive system

The image shows the most important connectors of a power supply module (left) and a driver module (right). Please refer to the technical documentation for details about other connectors.

- (1)

X7: USB connector (for driver configuration) on driver module

The driver module is configured using the PC configuration software PANATERM. Use a commercially available USB A to mini-B cable to connect the PC to the driver module.

- (2)

X104: DC link bus connectors on power supply module and driver module (535V DC to 675V DC), (3) X12: Control bus (24V DC) connectors on power supply module and driver module

Attach the bus bars to X104 and X12 to connect the DC circuits of the power supply module and the driver module.

- (4)

Connectors for DC circuits without and with bus bars

Wiring of the emergency stop button

Connect the emergency stop button to the safety I/O signal connector (X5) of the driver module.

- (1) X5: Safety I/O signal connector on driver module

Pin 15: Grouped safety digital input 1A

Pin 16: Safety input common A

Pin 17: External power supply (24V DC) for safety I/O

Pin 32: Grouped safety digital input 1B

Pin 33: Safety input common B

Pin 34: External ground

USB license dongle

A USB license dongle is required to compile and download the functional safety configuration to the driver module. Connect the license dongle to a USB port of your PC.

USB license dongle

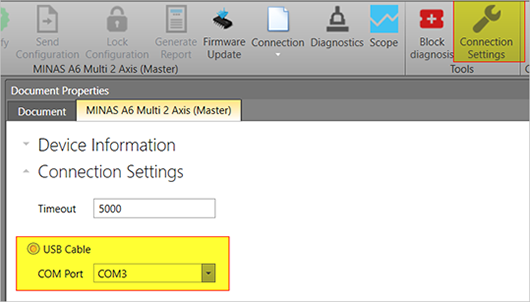

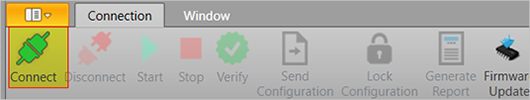

Connect the PC and the driver module

Connect your PC and the driver module with an Ethernet cable or with a USB cable. In this example, we use a USB cable that is connected to X8 of the driver module.

X8 connector (for functional safety configuration)

Use a commercially available USB A to mini-B cable to connect the PC to the driver module.

- (1) X8: USB connector on driver module

Functional safety configuration

Install PANATERM for Safety on your PC

Install the software on your PC.

For details, refer to the PANATERM for Safety Programming Manual SX-DSV03508.

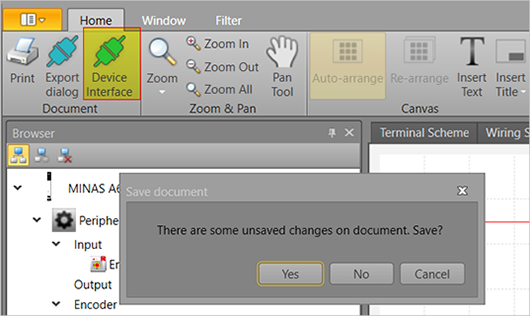

Create a safety program

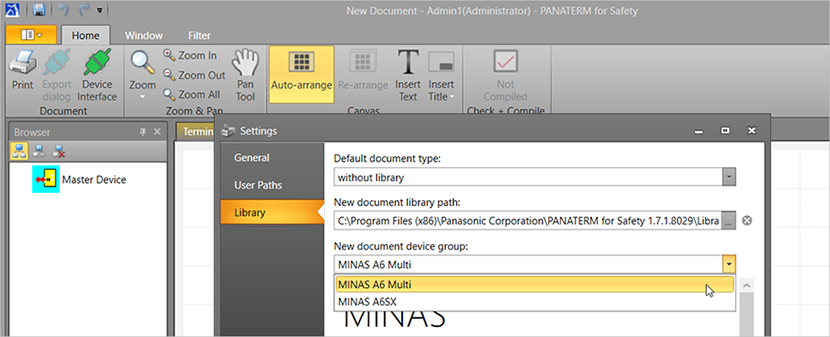

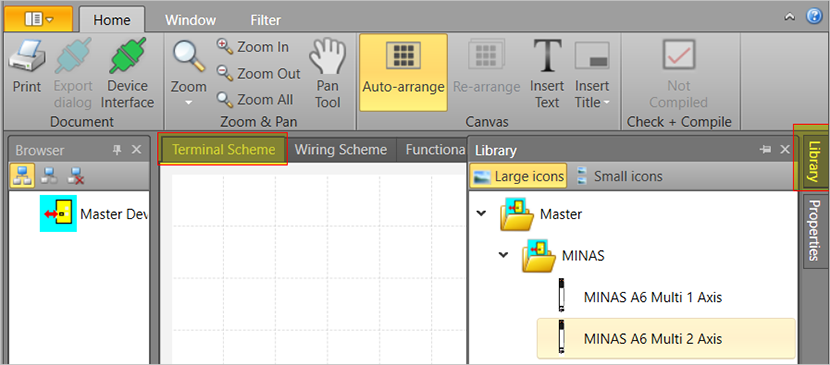

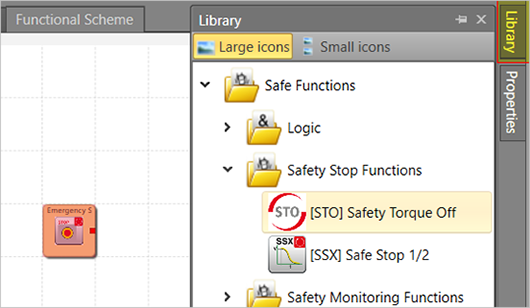

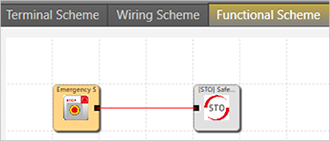

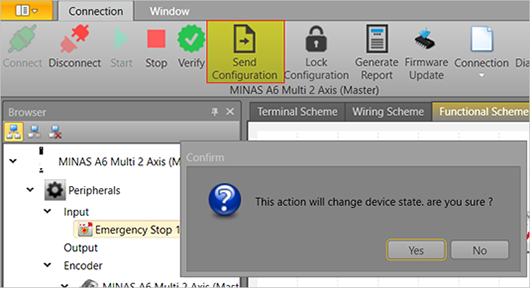

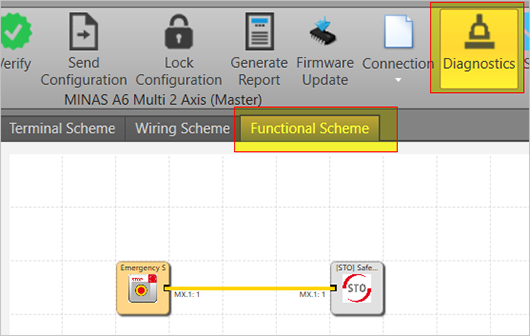

The general workflow for creating a safety program is to add the devices of your servo drive system to your project, to place them in the Terminal Scheme screen, and to configure the safety functions in theFunctional Scheme screen.

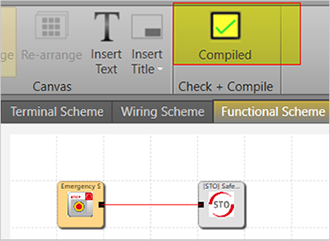

Download the safety program to the driver module

Remember that a USB license dongle is required to compile and save your program.