Torque control

Before you start

Before operating this product, read the safety instructions in the related Operating Instructions.

This product is for industrial use only.

Electrical connections must be made by qualified electrical personnel.

About this document

Step-by-step instructions will guide you through connecting a PLC to a MINAS servo driver and setting the most important parameters in the PANATERM configuration software.

Available software

The following software is available free of charge.

-

This link will take you to the Panasonic Industry Co., Ltd. Web site.

Functional overview

Torque control is a control mode to change the motor torque. The torque is controlled by analog signals (e.g. 0 to 10V) at the analog inputs of the servo driver. In addition to a torque signal, a speed limit signal is required to limit the motor speed. There are three different torque control modes (torque commands).

This Quick Start Guide describes torque command 0, which uses analog input 1 and a motor speed limit.

Example

An FP0RA21 analog output unit and a MINAS A6SF servo driver are connected using a DVOP4360V cable. An analog signal of 0 to 10V is sent from the unit to the servo driver. Additional signals, e.g. the servo ready or alarm status of the servo driver can be transmitted via the same cable to the PLC.

Wiring

Recommendations for wiring

It is the customer's responsibility to apply the countermeasures that they consider necessary to comply with current regulations on wiring, safety and reducing EMI.

Do not forget to meet the specifications indicated in the hardware manual for each of the devices being wired. If any specifications in the manual conflict with the information in this document, the manufacturer's manual takes preference.

For detailed information on reducing EMI, please refer to Recommendations for EMC-compliant wiring of servo drivers and motors.

Connectors of the servo driver

XA connector (main power connector)

Connect the power supply cable to the XA connector. For a 1-phase power supply of 230V, connect a 2-wire cable to the servo driver as illustrated. The L2 pin is not used in 1-phase mode.

XB connector (motor connector)

Connect the motor cable to the XB connector. The wires are labeled with the letters U, V, and W. Do not change the sequence of the motor phases, e.g. by connecting V to W.

X6 connector (encoder connector)

Connect the encoder cable to the X6 connector.

X4 connector (I/O connector)

Connect the connection cable to the X4 connector to the analog output unit.

X1 connector (USB connector for PC connection)

The servo driver is configured using the PANATERM configuration software . Use a commercially available USB A to mini-B cable to connect the PC to the servo driver.

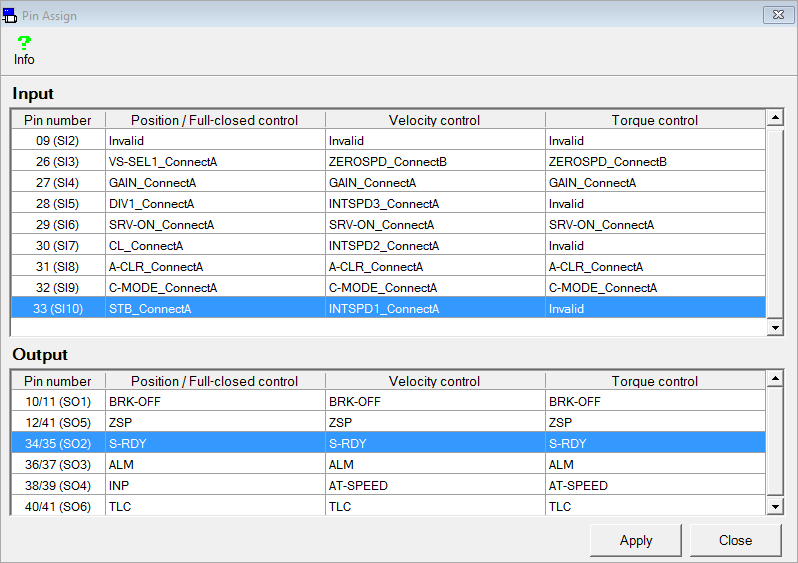

Signal inputs and outputs of the X4 connector

For torque control, the X4 connector of the MINAS A5/A6 servo driver is equipped with an analog input which has a resolution of 16 bits. The voltage range is 0V to +/-10V. The analog input is highlighted in the wiring diagram.

In our example, we will use the following signal inputs and outputs:

-

SRV-ON (pin 29)

Servo-on input to energize the servo motor.

-

COM+ (pin 7)

Common input for the power supply of the control signals.

-

SPR/TRQR/SPL (pins 14–15)

Analog torque command input.

-

S-RDY (pins 34–35)

Servo-ready output to indicate the ready state of the servo driver.

-

ALM (pins 36–37)

Servo-alarm output

-

AT-SPEED (pins 38–39)

Speed attainment output which turns on when the speed specified with Pr4.36 is reached.

Please refer to the Operating Instructions of your MINAS A5/A6 servo driver to learn more about the signal inputs and outputs which might be useful for your application.

PNP wiring of the X4 connector

NPN wiring of the X4 connector

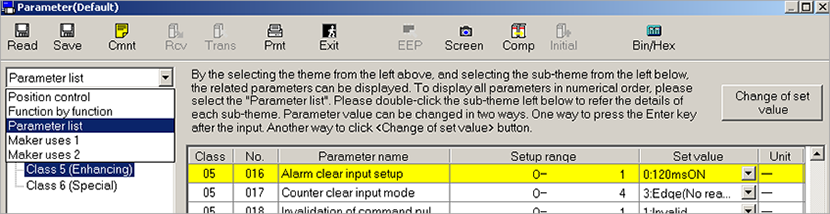

Make parameter settings in PANATERM

Use the PANATERM configuration software to configure the MINAS servo driver.

Basic parameters overview

The following table shows the setting range and description of the basic parameters.

Parameter |

Range |

Description |

|---|---|---|

Pr0.01 |

0 to 6 |

Control mode |

Pr3.17 |

0 to 2 |

Torque command input |

Pr3.18 |

0 to 1 |

Torque command direction |

Pr3.19 |

10 to 100 [0.1V/100%] |

Input gain of torque command |

Pr3.20 |

0 to 1 |

Inversion of torque command input |

Pr3.21 |

0 to 20000 [ms/(1000r/min)] |

Speed limit value 1 |

Pr4.22 |

-27888 to 27888 LSB (MINAS A5) -5578 to 5578 LSB (MINAS A6F) |

Analog input 1 offset |

Pr4.23 |

0.00 to 64.00 [ms] (MINAS A5, MINAS A6F) |

Analog input 1 filter |

Pr4.36 |

10 to 20000 [r/min] |

Speed attainment |

Pr0.01 (Control mode)

PANATERM parameter: Control mode setting

Setting range: 0 to 6

Select 2: Torque control

Pr3.17 (Torque command input)

PANATERM parameter: Torque command selection

Setting range: 0 to 2

- 0: Analog input 1, 16-bit resolution, speed limit specified using Pr3.25

- 1: Analog input 2, 12-bit resolution, speed limit specified by analog input 1

- 2: Analog input 1, 16-bit resolution, speed limit specified by Pr3.21, Pr3.22

Pr3.18 (Torque command direction)

PANATERM parameter: Torque command direction designation selection

Setting range: 0 to 1

- 0: Sign of torque command (positive torque command for positive direction, negative torque command for negative direction)

- 1: TC-SIGN input (OFF: positive direction, ON: negative direction)

Pr3.19 (Input gain of torque command)

PANATERM parameter: Torque command input gain

Setting range: 10 to 100 [0.1V/100%]

Set a gain factor for the motor torque based on the voltage applied at the torque command input TRQR. For example, a setting value of 30 results in a torque of 100% for an input voltage of 3V.

Pr3.20 (Inversion of torque command input)

PANATERM parameter: Torque command input inversion

Setting range: 0 to 1

- 0: No inversion, positive rotation direction for positive voltage

- 1: Inversion, positive rotation direction for negative voltage

Pr3.21 (Speed limit value 1)

PANATERM parameter: Speed limit value 1

Setting range: 0 to 20000

Default value: 0

Specify the speed limit used for torque control.

Pr4.22 (Analog input 1 offset)

PANATERM parameter: Analog input 1 (A|1) offset setting

- -27888 to 27888 LSB (MINAS A5)

- -5578 to 5578 LSB (MINAS A6F)

The default value is 0.

Specify an offset value to apply a torque on the motor shaft which compensates for drift.

Pr4.23 (Analog input 1 filter)

PANATERM parameter: Analog input 1 (A|1) filter setting

Setting range: 0.00 to 64.00 [ms]

The default value is 0.

This parameter acts like a low-pass filter to produce a stable voltage: the higher the setting value, the longer the delay.

Pr4.36 (Speed attainment)

- At-speed (MINAS A5)

- Attainment speed (MINAS A6)

Setting range: 10 to 20000 [r/min]

The default value is 1000r/min.

When the motor speed specified by this parameter is reached, the output AT-SPEED turns on.

Make pin assignments in PANATERM

For some applications, the software function of physical pins of the servo driver must be changed. Use the PANATERM configuration software to make the pin assignment.