Position control with SIMATIC S7-1200 host controller over Modbus RTU

Before you start

Before operating this product, read the safety instructions in the related Operating Instructions. This product is for industrial use only. Electrical connections must be made by qualified electrical personnel.

Related documents

Configuration

In this example, a SIMATIC S7-2100 PLC is connected to a MINAS A6SF servo driver via Modbus RTU.

A communication board for the PLC is required for the communication, as the CPU does not include Modbus RTU communication as standard.

Use a dedicated communication cable for the RS485 connection to the communication board.

The following hardware and software are used in this example:

Devices:

MINAS A6SF series servo driver and motor

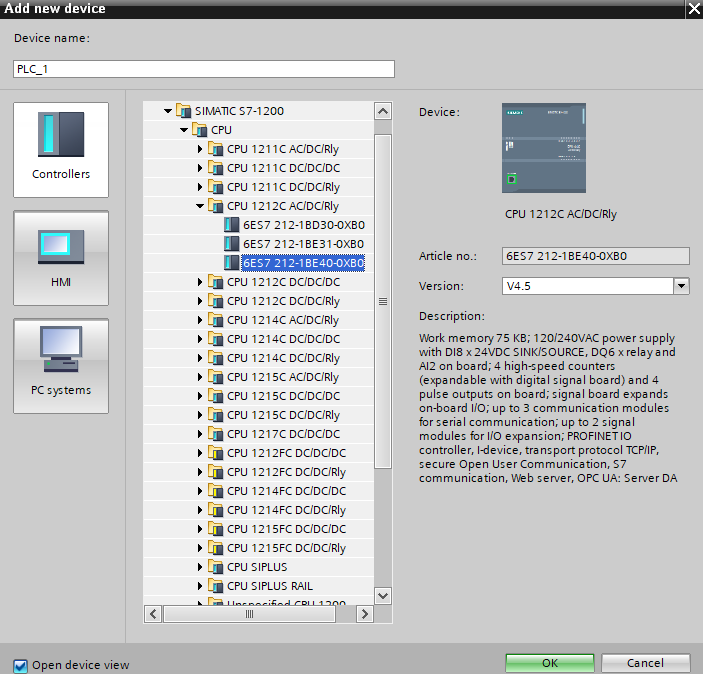

SIMATIC S7-1200 PLC (6ES7-212-1BE40-0XB0), firmware version 4.7.0

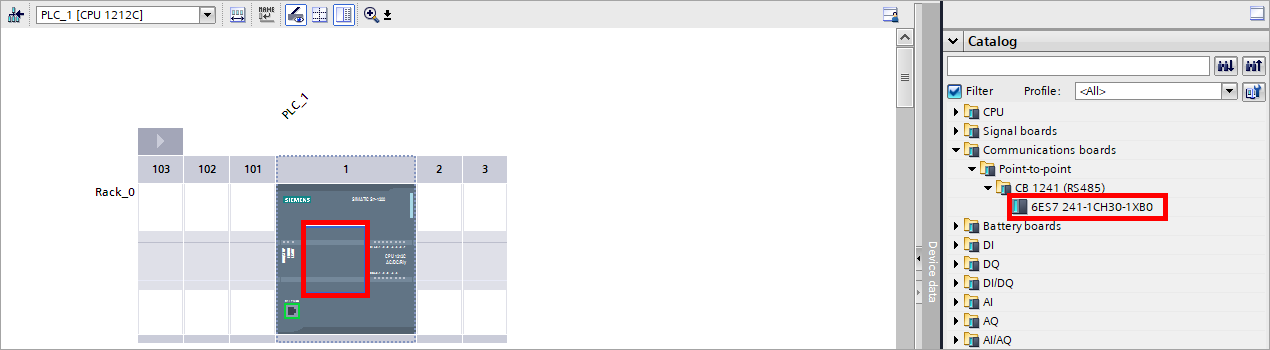

SIMATIC S7-1200 communication board CB 1241, RS-485 (6ES7-241-1CH30-1XB0)

Cable:

RS485/RS232 communication cable for MINAS A6 (X2), 8-pin, 2m QUAE0002071 (DV0PM20024CAB)

Software:

STEP 7 (TIA Portal) V17

PANATERM set-up support software (available free of charge)

Wiring

Recommendations for wiring

It is the customer's responsibility to apply the countermeasures that they consider necessary to comply with current regulations on wiring, safety and reducing EMI.

Do not forget to meet the specifications indicated in the hardware manual for each of the devices being wired. If any specifications in the manual conflict with the information in this document, the manufacturer's manual takes preference.

For detailed information on reducing EMI, please refer to Recommendations for EMC-compliant wiring of servo drivers and motors.

Connect the servo driver

XA connector (main power connector)

Connect the power supply cable to the XA connector. For a 1-phase power supply of 230V, connect a 2-wire cable to the servo driver as illustrated. The L2 pin is not used in 1-phase mode.

XB connector (motor connector)

Connect the motor cable to the XB connector. The wires are labeled with the letters U, V, and W. Do not change the sequence of the motor phases, e.g. by connecting V to W.

X6 connector (encoder connector)

Connect the encoder cable to the X6 connector.

X2 connector (serial communication port)

Connect the serial communication cable QUAE0002071 (DV0PM20024CAB020) to the X2 connector and to the communication board of the S7-1200 PLC.

Make the following connections:

TA must be connected with T/RA, and TB with T/RB.

The TA-T/RA jumper must be connected to the negative terminal of the servo driver.

The TB-T/RB jumper must be connected to the positive terminal of the servo driver.

The GND connection with M is not required.

X1 connector (USB connector for PC connection)

The servo driver is configured using the PANATERM configuration software . Use a commercially available USB A to mini-B cable to connect the PC to the servo driver.

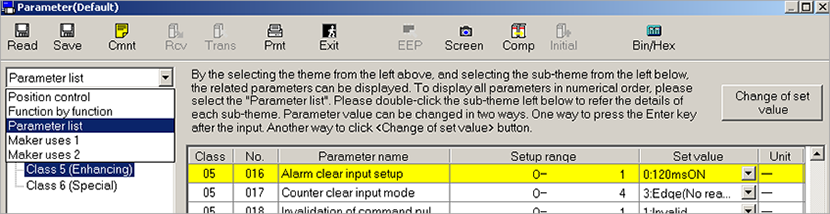

Make parameter settings in PANATERM

Use the PANATERM configuration software to configure the MINAS servo driver.

Basic parameters overview

The following table shows the setting range and description of the basic parameters.

Parameter |

Range |

Description |

|---|---|---|

Pr0.00 |

0 or 1 |

Motor rotation direction |

Pr0.01 |

0 to 6 |

Control mode |

Pr0.08 |

0 to 1048576 [pulse] (MINAS A5) 0 to 8388608 [pulse] (MINAS A6) |

Number of pulse signals per motor revolution |

Pr4.05 |

0 to 16777215 |

Function assignment for pin 29 of X4 connector |

Pr5.29 |

0 to 7 |

RS232C baud rate |

Pr5.30 |

0 to 7 |

RS485 baud rate |

Pr5.31 |

0 to 127 |

Axis number |

Pr5.37 |

0 to 2 |

Communication protocol |

Pr5.38 |

0 to 5 |

Modbus parity and stop bit setting |

Pr5.39 |

0 to 10000 |

Modbus response waiting time |

Pr6.28 |

0 to 2 |

Block operation mode |

Pr0.00 (Motor rotation direction)

PANATERM parameter: Rotational direction setting

Setting range: 0 or 1

The default value is 1: Rotation in CCW direction (counterclockwise direction).

Pr0.01 (Control mode)

PANATERM parameter: Control mode setting

Setting range: 0 to 6

The default value is 0: Position control

Select 0: Position control (block operation mode only supports position control)

Pr0.08 (Number of pulse signals per motor revolution)

PANATERM parameter: Command pulse number per one motor revolution

Setting range: 0 to 8388608 [pulse]

The default value is 10000 pulses per motor revolution.

Pr4.05 (Function assignment for pin 29 of X4 connector)

PANATERM parameter: SI6 input selection

Setting range: 0 to 16777215

The default value is 197379: servo-on input

Select 0 to disable the default pin assignment.

Pr5.30 (RS485 baud rate)

Set this parameter if the servo driver is connected via RS485.

PANATERM parameter: RS485 communication baud rate setting

Setting range: 0 to 7 (2400 to 230400bit/s)

The default value is 2 (9600bit/s).

Make sure the baud rate setting in the PLC program and in the servo driver are identical.

Pr5.31 (Axis number)

PANATERM parameter: Axis number

Setting range: 0 to 127

The default value is 1.

Select a value between 1 and 127. 0 is not accepted with Modbus RTU. Make sure the axis number setting in the PLC program and in the servo driver are identical.

Pr5.37 (Communication protocol)

PANATERM parameter: Modbus connection setting

Setting range: 0 to 2

The default value is 0 (MINAS standard protocol).

Select 2: Modbus-RTU (RS485 communication).

Pr5.38 (Modbus parity and stop bit setting)

PANATERM parameter: Modbus communication setting

Setting range: 0 to 5

The default value is 0: Even/1 bit

Make sure the parity and stop bit setting in the PLC program and in the servo driver are identical.

Pr5.39 (Modbus response waiting time)

PANATERM parameter: Modbus response waiting time

Setting range: 0 to 10000

The default value is 0.

Pr6.28 (Block operation mode)

PANATERM parameter: Special function selection

Setting range: 0 to 1

The default value is 0.

Select 1: Block operation valid (Modbus)

Set up the host controller

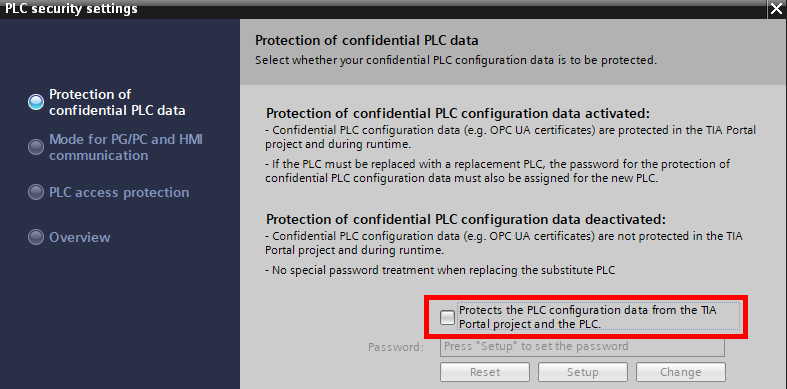

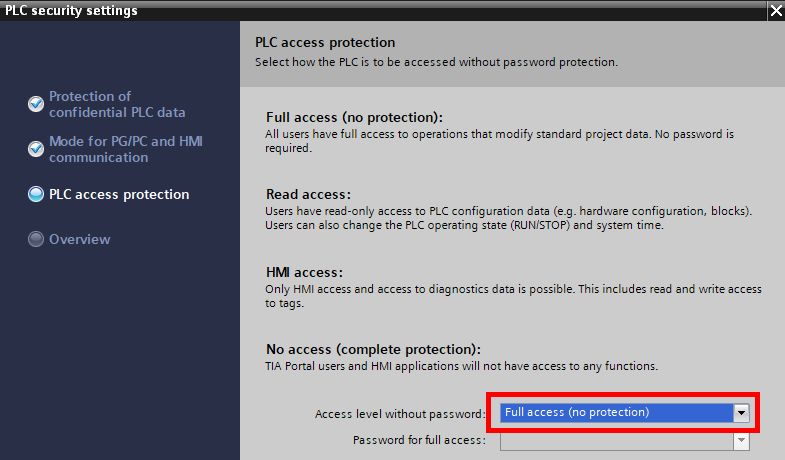

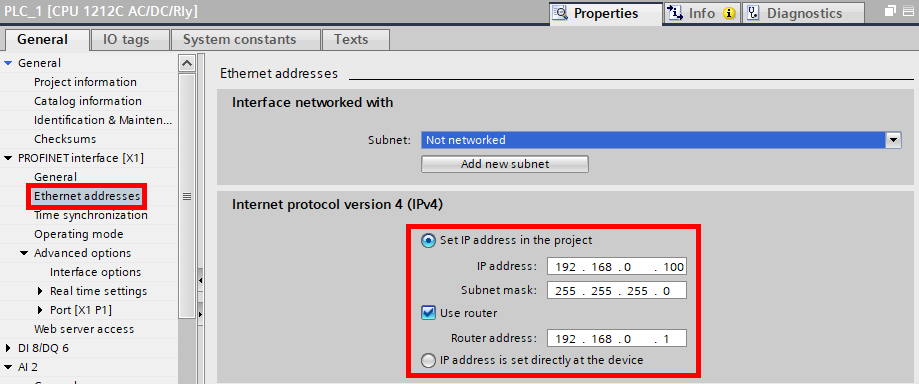

Create a new project in TIA Portal

When you create a new project in TIA Portal, select the PLC to be used, add the communication board, and set the IP address.

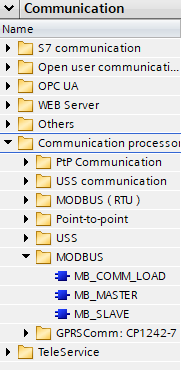

Create a PLC program

In the Communication task card, display the MODBUS instructions in the Communication processor block. Add MB_COMM_LOAD and MB_MASTER to the Main program block.

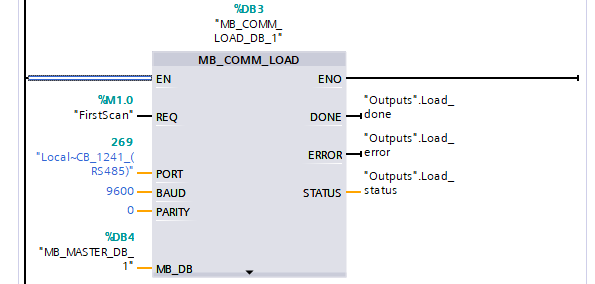

MB_COMM_LOAD

Use the MB_COMM_LOAD instruction to configure the port on the Modbus RTU communication board.

Input

- EN

Enables the instruction.

- REQ

A rising edge starts the operation. It is recommended to allow edge detection on the first cycle (FirstScan tag).

- PORT

Set the communication port.

- BAUD

Set the communication baud rate. It must match the setting of Pr.5.30 in the PANATERM configuration software.

Values:- 300, 600, 1200, 2400, 4800, 9600, 19200, 38400, 57600, 76800, 115200

- PARITY

Set the communication parity. It must match the setting of Pr.5.38 in the PANATERM configuration software.

Values:- 0: None

- 1: Odd

- 2: Even

- MB_DB

Set the name of the MB_MASTER instruction.

Output

- ENO

TRUE if the function is executed without error.

- DONE

TRUE for one scan after the last request was completed with no error.

- ERROR

TRUE for one scan after the last request was terminated with an error.

- STATUS

Returns the error code.

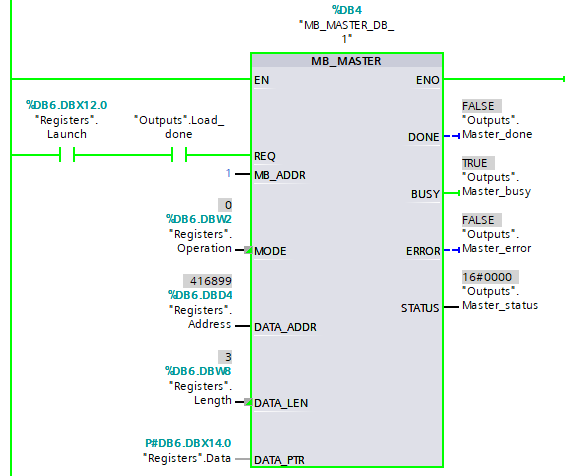

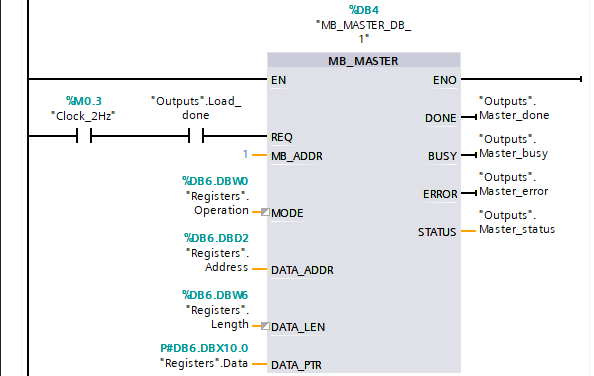

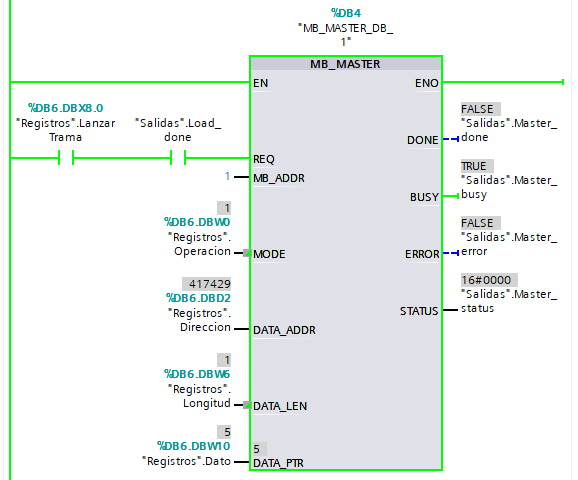

MB_MASTER

Use the MB_MASTER instruction to transmit data to the Modbus RTU slave.

Input

- EN

Enables the instruction.

- REQ

Set the conditions for data transmission to the Modbus RTU slave. In this example, the configuration instruction MB_COMM_LD is executed every 0.5s.

- MB_ADDR

Set the slave ID. It must match the setting of Pr.5.31 in the PANATERM configuration software.

- MODE

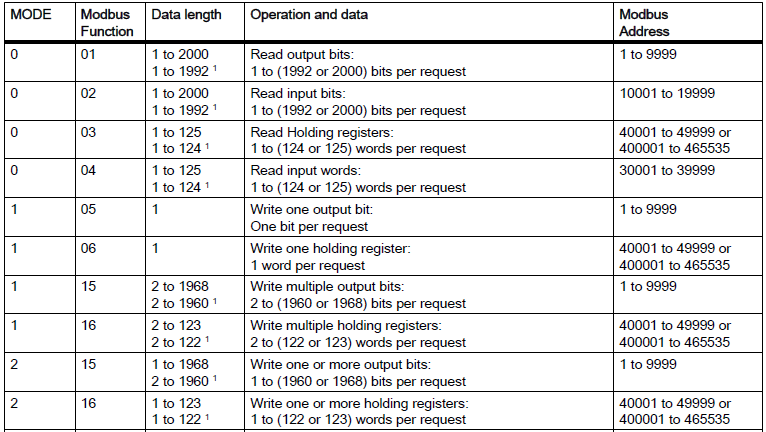

Set the operation type.

Values:- 0: Read

- 1: Write

- DATA_ADDR

Set the starting address of the data to be accessed in the slave. See the Modbus functions table for valid addresses.

Source: S7-1200 Programmable controller, System Manual, V4.4 11/2019, A5E02486680-AN

NOTEYou must add 1 to the Modbus address given in the Technical Reference - Modbus communication and block operation specification (SX-DSV03042).- DATA_LEN

Set the number of bits or words to be accessed. See the Modbus functions table for valid lengths.

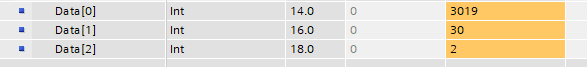

- DATA_PTR

Points to the variable that receives the data to be read or sets the data to be written. Use an array to read or write multiple registers.

Output

- ENO

TRUE if the function is executed without error.

- DONE

TRUE for one scan after the last request was completed with no error.

- BUSY

- Values:

- 0: No operation in progress

- 1: Operation in progress

- ERROR

TRUE for one scan after the last request was terminated with an error.

- STATUS

Returns the error code.

Programming examples

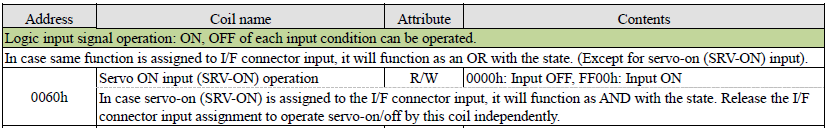

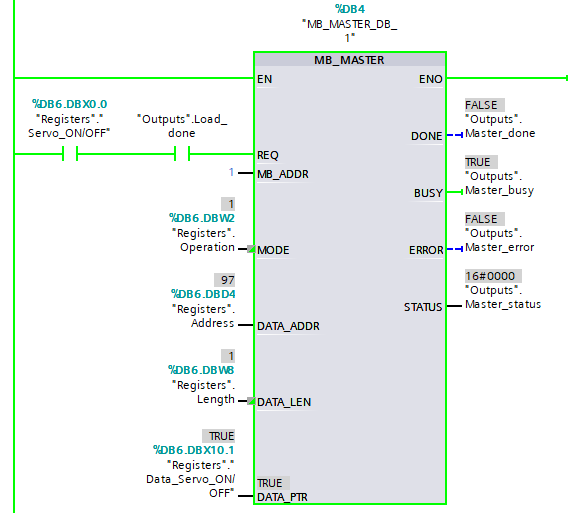

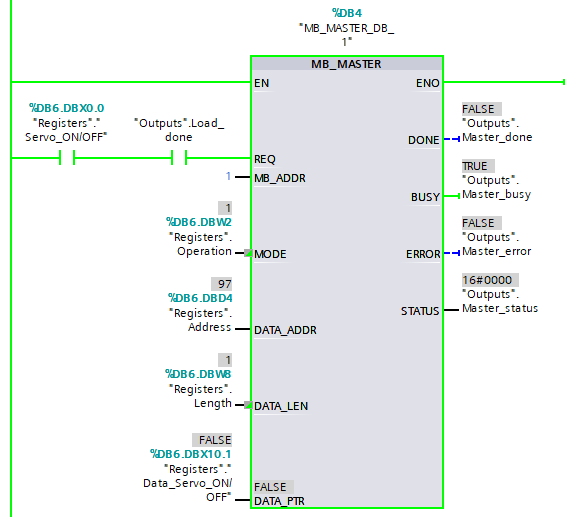

Set Servo ON - Servo OFF

To send a servo ON request signal to the servo driver, set the Modbus address of the SERV-ON operation at DATA_ADDR and turn DATA_PTR to TRUE.

To send a servo OFF request, turn DATA_PTR to FALSE.

You must add 1 to the Modbus address given in the Technical Reference - Modbus communication and block operation specification (SX-DSV03042).

In this example, set 97 (0060h = 96) for DATA_ADDR.

Source: Technical Reference - Modbus communication and block operation specification (SX-DSV03042)

Set a block command number

To execute a block command, set the Modbus address for block numbers at DATA_ADDR and set the block command number at DATA_PTR. In this example, we will set block command number 5.

You must add 1 to the Modbus address given in the Technical Reference - Modbus communication and block operation specification (SX-DSV03042). The Modbus address is preceded by the function code 4.

In this example, set 417429 (4202h = 17428, function code = 4) for DATA_ADDR.

Source: Technical Reference - Modbus communication and block operation specification (SX-DSV03042)

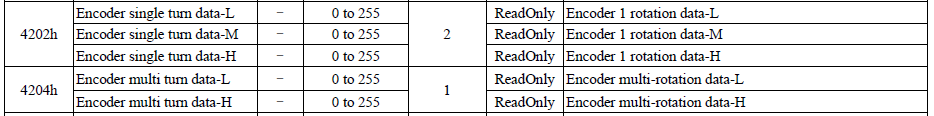

Read the encoder position

To read the encoder position, set the Modbus address for single-turn or multi-turn operations at DATA_ADDR. DATA_PTR points to the data bytes of the position value.

You must add 1 to the Modbus address given in the Technical Reference - Modbus communication and block operation specification (SX-DSV03042). The Modbus address is preceded by the function code 4.

In this example, set 416899 (4202h = 16898, function code = 4) for DATA_ADDR.

Source: Technical Reference - Modbus communication and block operation specification (SX-DSV03042)