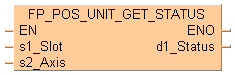

FP_POS_UNIT_GET_STATUS

FP_POS_UNIT_GET_STATUSGet axis status of positioning unit

This FP instruction reads the status data from the positioning unit in the slot specified by s1_Slot and for the axis specified by s2_Axis if the trigger EN is TRUE. The result is stored in d1_Status.

Input

Slot number

Axis number

Values: 1–4, 8 (virtual axis)

Output

Status information

Types of axis status information

Bit |

Status information |

TRUE |

|---|---|---|

0 |

Tool operation |

during tool operation of any axis configured with Configurator PM |

1 |

Error |

if an error occurred on the specified axis |

2 |

Warning |

if a warning was issued for the specified axis |

3 |

Busy |

if the specified axis is operating |

4 |

Operation done |

if operation is completed on the specified axis |

5 |

Home return done |

if home return is completed on the specified axis |

if the area specified using the index modifier exceeds the limit.

if the slot and/or axis number is out of range

if the area specified using the index modifier exceeds the limit.

if the slot and/or axis number is out of range

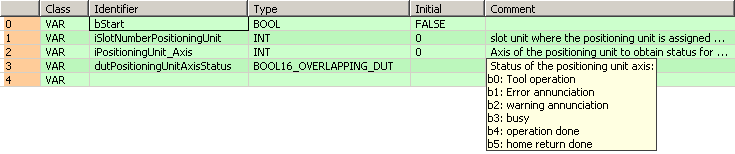

All input and output variables used for programming this function have been declared in the POU header. The same POU header is used for all programming languages.

VAR

bStart: BOOL:=FALSE;

iSlotNumberPositioningUnit: INT:=0;

(*slot unit where the positioning unit is assigned 1- 64*)

iPositioningUnit_Axis: INT:=0;

(*Axis of the positioning unit to obtain status for (1-4: axis; 8: virtual axis)*)

dutPositioningUnitAxisStatus: BOOL16_OVERLAPPING_DUT;

(*Status of the positioning unit axis:

b0: Tool operation

b1: Error annunciation

b2: warning annunciation

b3: busy

b4: operation done

b5: home return done*)

END_VARWhen the variable bStart is set to TRUE, the function is carried out.

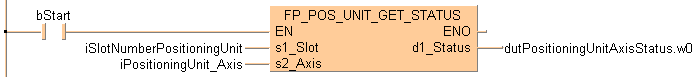

BODY

WORKSPACE

NETWORK_LIST_TYPE := NWTYPELD ;

ACTIVE_NETWORK := 0 ;

END_WORKSPACE

NET_WORK

NETWORK_TYPE := NWTYPELD ;

NETWORK_LABEL := ;

NETWORK_TITLE := ;

NETWORK_HEIGHT := 6 ;

NETWORK_BODY

B(B_F,FP_POS_UNIT_GET_STATUS!,,17,1,31,6,,?DEN?Ds1_Slot?Ds2_Axis?AENO?Cd1_Status);

B(B_VARIN,,iSlotNumberPositioningUnit,15,3,17,5,);

B(B_VARIN,,iPositioningUnit_Axis,15,4,17,6,);

B(B_VAROUT,,dutPositioningUnitAxisStatus.w0,31,3,33,5,);

B(B_CONTACT,,bStart,3,2,5,4,);

L(5,3,17,3);

L(1,3,3,3);

L(1,0,1,6);

END_NETWORK_BODY

END_NET_WORK

END_BODY

IF bStart then

FP_POS_UNIT_GET_STATUS(s1_Slot := iSlotNumberPositioningUnit,

s2_Axis := iPositioningUnit_Axis,

d1_Status => dutPositioningUnitAxisStatus.w0);

END_IF;