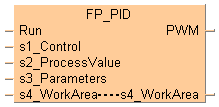

FP_PID

FP_PIDPID processing with optional PWM output

PID processing is performed to keep the process value PV as close as possible to the set point value SP. In contrast to FP_PID_BASIC, this instruction enables a PWM output (on-off output). Auto-tuning is also available to automatically calculate the PID control data Kp, Ti, and Td.

Input

Start condition

Control data

Process value (-30000–30000)

PID control parameters

Input/output

Data table of PID parameters

When you execute the instruction for the first time, i.e. when the execution condition specified at Run turns to TRUE, the default values are written to the DUT members 1 to 9 of DUT .

Before the second execution of FP_PID, you need to change the DUT members 1 to 9 of the DUT to the required values.

Output

Pulse-width modulated output (optional, can be used instead of manipulated value output)

The period (cycle) of the PWM output is the sampling time Ts (the frequency of the PWM output is 1/Ts) and the duty is the manipulated value MV in 0.01% units, e.g. MV = 10000 means a duty of 100%.

The instruction has to be executed twice. The first execution resets the values in PID_WORK_AREA_DUT, then the correct values for the DUT members 1 to 9 in PID_WORK_AREA_DUT need to be set so that the second execution of the instruction uses the correct values.

if the area specified using the index modifier exceeds the limit.

if a value specified for a parameter of PID_Parameters_DUT is outside the permissible range

if the area specified using the index modifier exceeds the limit.

if a value specified for a parameter of PID_Parameters_DUT is outside the permissible range

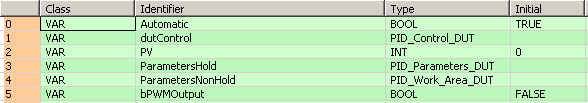

All input and output variables used for programming this function have been declared in the POU header. The same POU header is used for all programming languages.

VAR

Automatic: BOOL:=TRUE;

dutControl: PID_Control_DUT;

PV: INT:=0;

ParametersHold: PID_Parameters_DUT;

ParametersNonHold: PID_Work_Area_DUT;

bPWMOutput: BOOL:=FALSE;

END_VAR

BODY

WORKSPACE

NETWORK_LIST_TYPE := NWTYPELD ;

ACTIVE_NETWORK := 0 ;

END_WORKSPACE

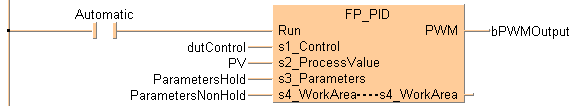

NET_WORK

NETWORK_TYPE := NWTYPELD ;

NETWORK_LABEL := ;

NETWORK_TITLE := ;

NETWORK_HEIGHT := 7 ;

NETWORK_BODY

B(B_VARIN,,dutControl,15,2,17,4,);

B(B_VARIN,,ParametersHold,15,4,17,6,);

B(B_CONTACT,,Automatic,6,1,8,3,);

B(B_VARIN,,ParametersNonHold,15,5,17,7,);

B(B_F,FP_PID!,,17,0,30,7,,?DRun?Ds1_Control?Ds2_ProcessValue?Ds3_Parameters?Ds4_WorkArea?As4_WorkArea?APWM);

B(B_VARIN,,PV,15,3,17,5,);

B(B_VAROUT,,bPWMOutput,30,1,32,3,);

L(1,2,6,2);

L(8,2,17,2);

L(1,0,1,7);

END_NETWORK_BODY

END_NET_WORK

END_BODY

bPWMOutput := FP_PID(Run := Automatic,

s1_Control := dutControl,

s2_ProcessValue := PV,

s3_Parameters := ParametersHold,

s4_WorkArea := ParametersNonHold);